Public time:

2013-06-27 17:51

counts:

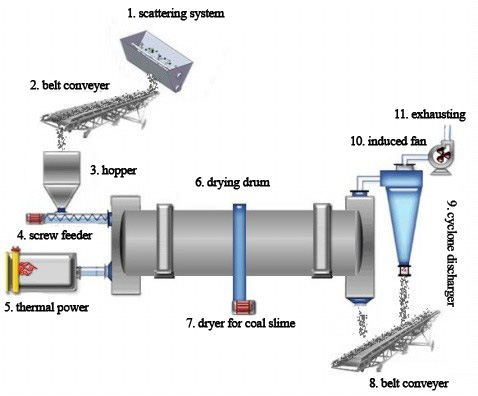

Drier machine is supplied by AGICO as an auxiliary equipment of biomass briquetting plant, many drier machine manufacturers claim that their machine can reach 0 failure rate, which is definitely a lie. For a machine which keeps running for almost 24 hours a day, all kinds of small faulty could occur, as an experienced

drier machine supplier, AGICO offers you the solutions to deal with those moments.

-

Low efficiency with high power consumption:

Cause: Thermal insulation property is not good enough; the design or installation of furnace need perfection.

Solution: wrap a layer of insulation material out of the drier; ask the manufacturer for a better furnace design.

-

Dried material moisture is not steady:

Cause: improper operation of the drier, raw material forms balls or other blocks inside in drier.

Solution: Ask the manufacturer for the details of the operation book; break the balls and dry them again.

-

Separator-Raw materials coming out of Chimney:

Cause: Separator is too small; the installation is not correct.

Solution: Ask the manufacturer to change the separator.

-

Raw material couldn’t be transferred out of the drier normally:

Cause: The installation of the drier is not good, gas leak may occur at the connection between the tubes.

Solution: fix the leak at between the tubes; ask the manufacturer to reinstall the drier.

Español

Español