There are four kinds of drying machine:

Coal Drying Machine

Coal Slime Dryer

Biomass Drying Machine

Twin Boiler Drying Machine

Rotary Drum Type Flash Drying Machine

GC-QL-I Drying Machine

Coal Slime Dryer

- For coal mining industry, such material as coal slime, raw coal,clean coal after floatation, mixed clean coal.

- For architecture industry, such material as blast furnace slag, clay, limestone, stand, quartz stones.

- For ore selecting industry, such material as ore concentrate , slag and tailings.

- For chemical industry, such material as the non-thermal sensitive.

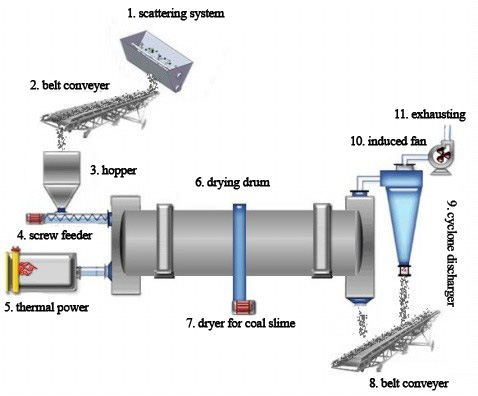

Featuring high moisture content and adhesive property, coal slime in the process of drying will be taken to the scattering system by the bond conveyer, and then the scattered material will be taken into the dryer full of negative pressure, after which the drying will be divided into several steps as follows:

Process Flow Diagram

- Guiding section. Upon entering into this section and blending with the high temp, negative pressure hot air, moist material will be promptly evaporated much and thanks to the shovelling plates, the material is tough to be bond together but led into next section.

- Cleaning section. Due to the work of shoveling plates, a vaporific curtain by the material will come into being and the drum internal walls will be bond with the material which will then be cleaned off swiftly by the cleaning device hereby, during which the coal slime lumps and agglomerates will also be crushed. Consequently, the heat exchange degree, ratio and the drying speed will all be increased.

- Shoveling section. Also called low temp drying zone. The coal slime hereinto remains slacked status with lower water content which means no possibility of bonding, however, after heat exchanging, the material will have met the requirement for water content and then go into next sections.

- Discharging section. Within the drying drum, there is no shoveling plate available. But the dried material will slide to the outlet.

- It consists mainly of such systems as heating, scattering, feeding, conveying, drying, dust collecting, electric controlling and crushing.

Technical Parameters

| Model/item | Drum inner dia. (M) | Drum length (M) | Motor power(kW) | Drum speed(r/min) | Overall size(L×W×H)(FOR REFERENCE) |

|---|---|---|---|---|---|

| GC-MNΦ1×8 | 1.0 | 8 | 5.5 | 3-6 | 8×1.9×2.1 |

| GC-MNΦ1×10 | 10 | 10×1.9×2.1 | |||

| GC-MNΦ1.2×10 | 1.2 | 10 | 10×1.9×2.1 | ||

| 7.5 | |||||

| GC-MNΦ1.2×12 | 12 | 12×1.9×2.1 | |||

| GC-MNΦ1.5×12 | 1.5 | 12 | 15 | 12×2.6×2.8 | |

| GC-MNΦ1.5×14 | 14 | 14×2.6×2.8 | |||

| GC-MNΦ1.8×14 | 1.8 | 14 | 14×3.0×3.0 | ||

| 18.5 | |||||

| GC-MNΦ1.8×18 | 18 | 22 | 18×3.0×3.0 | ||

| GC-MNΦ2×1.8 | 2.0 | 18 | 22 | 18×3.2×3.2 | |

| GC-MNΦ2.2×18 | 2.2 | 18 | 30 | 18×4.0×3.8 | |

| GC-MNΦ2.2×20 | 20 | 20×4.0×3.8 | |||

| GC-MNΦ2.4×18 | 2.4 | 18 | 18×4.0×3.8 | ||

| GC-MNΦ2.4×20 | 20 | 37 | 20×3.6×3.6 | ||

| GC-MNΦ2.8×14 | 2.8 | 14 | 75 | 14×4.6×4.6 | |

| GC-MNΦ2.8×18 | 18 | 18×4.6×4.6 | |||

| GC-MNΦ3×20 | 3.0 | 20 | 110 | 20×5.0×5.0 | |

| GC-MNΦ3.2×18 | 3.2 | 18 | 132 | 18×8.0×7.0 | |

| GC-MNΦ3.2×20 | 20 | 20×8.0×7.0 |

Twin Boiler Drying Machine for Sale

(For biomass materials with moisture content 20-50%)

| Model | GC-QL-II-7.5 | GC-QL-II-11 | GC-QL-II-15 |

| Capacity(Kg/hour) | 400-500KG | 500-700KG | 900-1000KG |

|

Size of Input Material (Diameter) |

< 3mm & < 5mm | < 3mm & < 5mm | < 3mm & < 5mm |

| Temperature of Hot Air | 180°C~250°C | 180°C~250°C | 180°C~250°C |

| Consumption of Wood Waste | 60kg/h | 100kg/h | 150kg/h |

| Moister content max % | 20-50% | 20-50% | 20-50% |

| Moisture of material after drying | 8-12% | 8-12% | 8-12% |

|

Power (Air Fan+Air Lock+ speed adjustable feed motor) |

7.5kw+0.75kw +0.75kw |

11kw+0.75kw +0.75kw |

15kw+0.75kw+0.75kw |

| Net/Gross Weight | 2040/2260kg | 2850/3080kg | 2850/3080kg |

| Overall dimension(L*W*H) | 9m*2.4m*4m | 9m*3.2m*4m | 9.5m*3.8m*4.5m |

| Packing size | 11 M3(3 cases) | 14 M3(3 cases) | 18 M3(3 cases) |

As its name suggests, this machine is equipped with two hot air boilers. It is one of our best selling drying equipment on the market. With advanced structure design, this drying machine is suitable for drying sawdust and a wide range of other materials (the moisture content is required to be 20% -50%). The moisture content of the final products can reach 8-12%.

PS: For materials with moisture 20-35%, the first boiler is enough, no need to use the both.

Rotary Drum Type Flash Drying Machine for Sale

(For biomass materials with moisture content 20-65% )

| Model | GC-MXΦ0.6×5 |

| Output Capacity(Kg/hour) | 800-1000KG |

| Size of Input Material(Diameter) | < 3mm & < 5mm |

| Temperature of Hot Air | 180°C~250°C |

| Moisture of raw material | 40%~70% |

| Consumption of Wood Waste | 20-30 kg/h |

| Power | 7.5 kw |

| Size of rotary | Diameter 630mm *L 5200mm |

| Net/Gross Weight | 2500/2600 kg |

| Installation Dimension(m) | 14*1.2*4.2 m |

| Loading in container | 1* 20’GP |

The key component of Rotary drying machine is material feeding plate, a rotary body, supporting and driving device. This machine is manufactured for materials of moisture 20-65%. It can deal with various different biomass materials including corn stalks, milled wheat straw, rice hulls and sawdust. If you are looking for a high efficiency and low cost drying machine, this one should be your best choice! The final moisture content of the powder material can reach 8-12%.

The feeding plate is designed reasonably with changeable angles. After feeding the prepared materials into the rotary body from the feeding plate, hot air will be generated by hot air-flow and the humidity of inside materials (sawdust for example) will be evaporated into vapor.

GC-QL-I Drying Machine for Sale

(For materials with lower moisture content 12-25%)

| Model | GC-QL-I-4 | GC-QL-I-7.5 | GC-QL-I-11 |

| Capacity(Kg/hour) | 200-250KG | 500-700KG | 800-900KG |

|

Size of Input Material (Diameter) |

< 3mm & < 5mm | < 3mm & < 5mm | < 3mm & < 5mm |

| Temperature of Hot Air | 180°C~250°C | 180°C~250°C | 180°C~250°C |

| Consumption of Wood Waste | 15-20 kg/h | 30-35kg/h | 30-35kg/h |

|

Power (Centrifugal Fan) |

4kw | 7.5kw/11kw+1.5kw | 11kw+1.5kw+0.75kw |

| Net/Gross Weight | 700/800kg | 1800/1900kg | 2110/2280kg |

| Dimension(m) | 6×2×3.65m | 11×2×3.65m | 11×2×3.65m |

GC-QL-I drying machine is a kind of efficient drying equipment for sawdust and other powder materials. The moisture reducing rate can reach 8-12%. It is designed with one hot air boiler so the moisture content of the raw materials is required to less than 25%. But if your materials have a higher moisture content, you can dry them two or three times to achieve the requirement for briquetting.

Looking for a durable sawdust drying machine for sale? AGICO GROUP is definitely your best choice! If you want more information about our company or our products, please do not hesitate to contact us.

Español

Español